Machine Trading

01

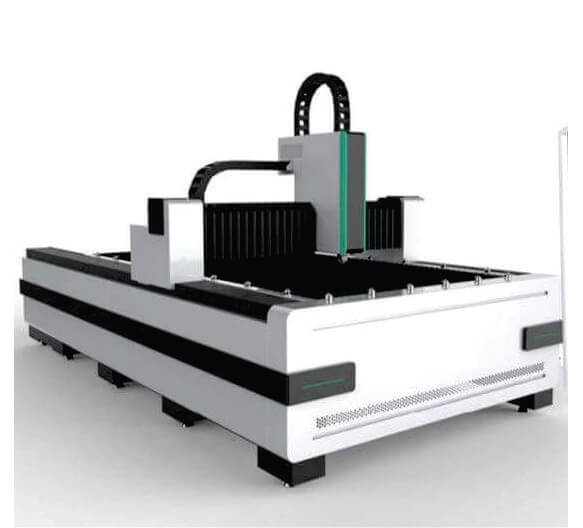

CTL (Cut-to-Length) Cutting Machine

Precision Cutting Solution for Coil-to-Sheet Metal Processing

The CTL Cutting Machine is engineered for accuracy and speed, converting metal coils into flat sheets of exact lengths. Ideal for various industries, it ensures consistent quality, reduced waste, and smooth operation — making it a reliable choice for high-volume sheet metal processing.

The CTL (Cut-to-Length) Cutting Machine is a precision industrial system designed to uncoil, level, and cut metal coils into specific sheet lengths.

Known for its high speed, accuracy, and minimal material waste, the CTL machine is essential for manufacturing processes that demand consistent, high-quality sheet metal production.

It is ideal for both light and heavy-duty applications across various thicknesses and materials like stainless steel, aluminum, copper, and mild steel.

02

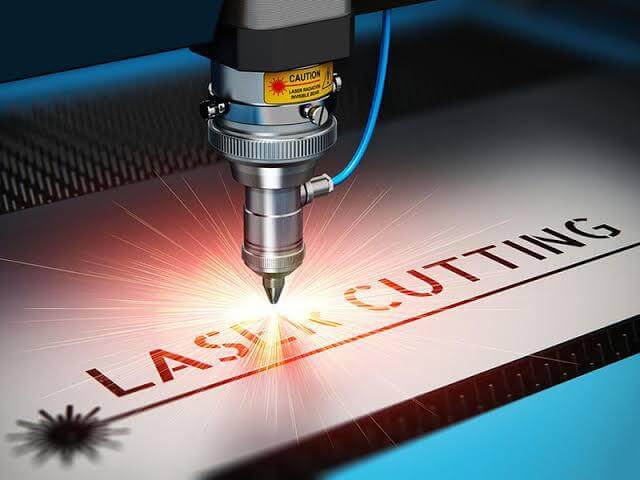

Laser Cutting Machine

High-Precision Cutting for Complex and Custom Metal Shapes

The Laser Cutting Machine is a state-of-the-art solution for cutting a wide range of materials, especially metals, with extreme precision and speed. Using a focused laser beam, this machine melts, burns, or vaporizes material with minimal edge distortion, allowing for smooth and complex cuts without physical contact.

Equipped with CNC (Computer Numerical Control) systems, the machine can process highly intricate patterns with high repeatability and minimal error. Whether cutting stainless steel, mild steel, aluminum, or non-metallic materials like acrylic and plastic, laser cutting ensures minimal waste and maximum efficiency.

Its automation capabilities reduce manual labor, increase productivity, and improve safety in the workplace. It is ideal for industries where precision, speed, and versatility are critical — such as automotive, aerospace, metal fabrication, electronics, and signage.

02

How It Works

From Coil to Precision-Cut Sheets – A Seamless, Automated Workflow

01

Uncoiling

Metal coils are loaded and fed into the machine’s decoiler to begin the cutting process.

02

Leveling

The coil passes through a leveling system to flatten the strip and eliminate internal stress.

03

Looping

A loop control system ensures consistent tension and smooth material flow.

04

Feeding

A servo-controlled feeder ensures accurate length control as the strip moves toward the shear.

05

Cutting

The sheet is cut to the desired length using high-precision mechanical or hydraulic shears.

06

Stacking

The cut sheets are automatically aligned and stacked for easy collection.

03

Bending Machine

Efficient Sheet Metal Forming for Industrial-Grade Bends and Folds

The Bending Machine, also known as a press brake, is designed to form sheet metal into precise shapes and angles through a controlled bending process. It uses mechanical, hydraulic, or CNC-driven systems to apply uniform pressure along the bend line, ensuring consistency even in complex part geometries.

Modern bending machines are equipped with programmable controls, allowing for multi-step operations, angle adjustments, and automated back gauge positioning. This results in reduced setup time and increased accuracy across production batches.

Capable of bending mild steel, stainless steel, aluminum, and other sheet metals of various thicknesses, the machine is commonly used in industries such as construction, HVAC, electrical panel manufacturing, furniture, and custom fabrication.

Its ability to perform V-bending, U-bending, air bending, and coining operations makes it a vital part of any metalworking line, especially where precision and repeatability are key.

Industries We Serve

Versatile Applications Across Major Manufacturing and Engineering Sectors

- Automotive Industry

- For manufacturing car body panels and structural components.

- Appliance Manufacturing

- In production of washing machines, refrigerators, and ovens.

- Construction & Infrastructure

- Roofing sheets, building facades, and steel panels.

- Electrical Industry

- Transformer laminations and control panel enclosures.

- Shipbuilding and Heavy Engineering

- Cutting large plates for ship hulls and structural frames.

- Metal Service Centers

- For supplying cut sheets to various downstream industries.